Modular system for mechanical seal of shafts or maneuvering propellers applicable to floating ship

The field of technology to which the invention refers explicitly to the naval field.

It is a pre-existing technique and currently used in America by the divers of Miami, and consists of an external wrapping system that does not allow the escape of oil into the sea and therefore the infiltration of water inside the propellers, which would damage the components of mechanical parts present inside them.

The drawback of this technique is the impossibility of using the propeller.

The invention to which we refer would intervene on the seal of the damaged propeller (one of the most frequent causes is the twining of the lines around the axis with consequent cutting of the seal).

As a consequence of the damage, the part begins to lose oil that escapes into the sea with an environmental impact of great importance with regard to pollution and marine life. Once all the oil has been lost, there is an infiltration of salt water inside the propellers which damages all the mechanical parts that compose them – bearings, gears, axle, pitch movement system, etc. – all parts that are naturally lubricated with oil.

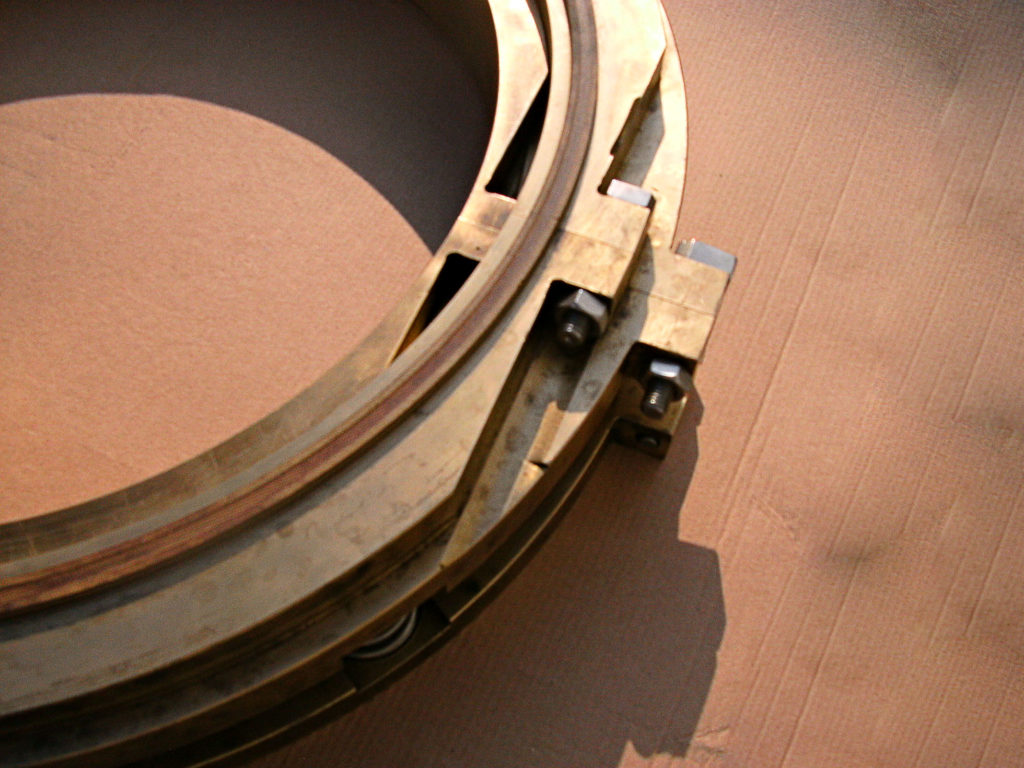

The solution that we are going to present is to put the propeller back into operation, eliminating the loss of oil, with the construction of a modular seal to be mounted underwater and then restore the functionality of the propeller.

At present, the ship must re-enter the dock with the aid of tugboats or request the wrapping of the propeller which compromises its operation with consequent additional costs for its normal operation.

The advantage obtained from the application of this invention is that the intervention takes place with the vessel in operation with consequent rapidity of intervention and reduction of the costs related to the repair.